Qinu GmbH Selects GF40 Mass Flow Controller for Precise Flow Performance in Gas Handling System for Quantum Technology

Pictured: GF40 mass flow controllers in Qinu’s gas handling system...

Quantum technologies, including quantum computing, quantum sensing, and quantum communication, are revolutionizing industries by leveraging the principles of quantum mechanics.

Testing these cutting-edge systems demand ultra-precise control of gas flow, pressure, and composition to maintain stable, ultra-pure environments critical for quantum coherence and performance. The Brooks Instrument thermal mass flow meter is engineered to meet these stringent requirements, offering unparalleled precision, reliability, and compatibility with the gas handling systems used in quantum technology applications.

Quantum devices rely on qubits (quantum bits) to function. To enhance the reliability of these processes, the qubits must be kept in a highly pure state, reducing any potential disturbances. As the purity of a qubit is closely tied to its temperature, achieving maximum purity requires cooling the qubits to the lowest possible temperatures. This cooling process is facilitated by the use of helium.

Precise Gas Flow Control of Helium

The refrigeration process uses a mixture of two isotopes of helium: Helium-3 (3He) and h=Helium-4 (4He). When cooled below approximately 870 millikelvins, the mixture undergoes spontaneous phase separation to form a 3He-rich phase (the concentrated phase) and a 3He-poor phase (the dilute phase). At very low temperatures the concentrated phase is essentially pure 3He, while the dilute phase contains about 6.6% 3He and 93.4% 4He. The working gas is a mixture which is circulated by vacuum pumps at room temperature.

Modern dilution refrigerators can precool the 3He with a cryocooler in place of liquid nitrogen, liquid helium, and a 1 K bath. No external supply of cryogenic liquids is needed in these "dry cryostats" and operation can be highly automated. These “dry cryostats” are part of Qinu’s system.

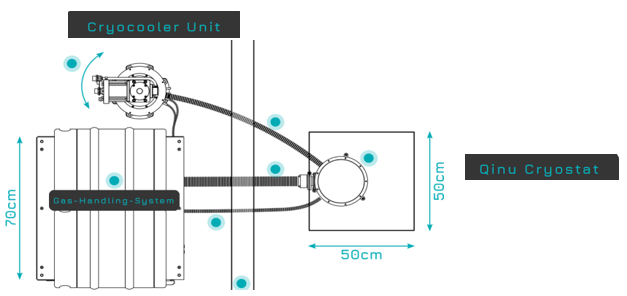

Pictured: Qinu GmbH gas handling system with “dry” cryocooler unit and Qinu cryostat

Pictured: Qinu GmbH gas handling system with “dry” cryocooler unit and Qinu cryostat

Qinu is a company that develops and manufactures high-tech gas handling systems for industry and research. Those cooling systems can generate extreme conditions such as very low temperatures (0.01 °C above absolute zero) and vacuum, as well as provide protection from electromagnetic radiation.

GF40 Series mass flow controllers from Brooks Instrument enable the precise control of Helium which will be used in the cooling process. The handling system contains 3 or 4 GF40 mass flow controllers depending on the end customer application.

The Qinu cryostat, the Gas-Handling System (GHS) and the Cryocooler Unit (CCU) can be positioned independently of each other. This provides maximum flexibility in layout design and enables the installation of the complete system in every lab environment.

Due to the flexible connections between the three subparts and in combination with the possibility to fix the corrugated tubes to a massive wall or floor, vibrations present at the experimental stage are highly reduced. In addition, all noise emitting sources can be placed in a separate room or soundproof box.

Application Requirements

The cooling process is the core of the application. During this process, Brooks Instrument GF40 mass flow controllers deliver the He4 and 3He /4He mixture to ensure precise and efficient cooling.

Highlights:

- High Precision and Accuracy: Flow control accuracies ±1% S.P. 35-100%, ±0.35% F.S. 2-35% and repeatability <± 0.2% S.P. ensuring stable experimental conditions.

- Ultra-Low Leak Rates: Leak integrity of 1x10-9 atm. cc/sec He, critical for cryogenic applications.

- Fast Response Times: Response times < 1 sec, enabling rapid adjustments during dynamic experiments.

- Material Compatibility: Constructed from 316 Stainless Steel, Hastelloy C-22, 17-7 PH, 430SS to prevent contamination.

- Wide Dynamic Range: Flow ranges from 3 sccm to 50 slm, accommodating diverse quantum applications.

- Advanced Control Options: Digital interfaces RS485, Profibus, DeviceNet, EtherCAT for seamless integration with quantum system control software.

- Custom Solutions: Tailored MFC designs and calibration services for exotic gases, isotopes, or specialized applications.

Precise Gas Flow Control of Helium

The Brooks Instrument GF40 thermal mass flow controller is a critical component of the entire cooling system, as it manages the delivery of helium, which is used for cooling, through GF40 mass flow meters.

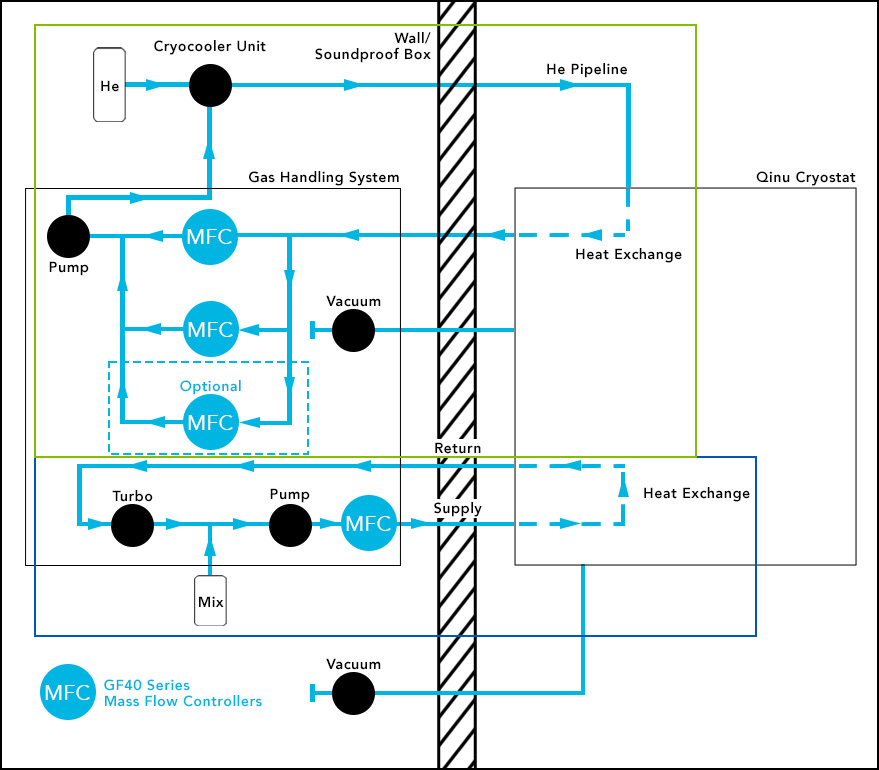

Qinu GmbH gas handling system flow schematic with GF40 Series mass flow controllers.

Qinu GmbH gas handling system flow schematic with GF40 Series mass flow controllers.

The system comprises two helium vessels. In the initial phase (depicted in green), two or three GF40 mass flow controllers regulate the gas flow of 4He at a rate of 40 liters per minute (lpm), cooling the system to a temperature of 3 Kelvin. In the subsequent phase (shown in blue), a mixture of 4He and 3He is controlled by a fourth GF40 mass flow controller, with a flow rate of 15–20 lpm, further reducing the temperature to a range of 10–30 millikelvin. The system operates under a pressure of 1 bar gauge.

The unparalleled precision, accuracy, and reliability of the GF40 mass flow controllers are critical instruments in this application setup where ultra-precise gas flow is paramount.