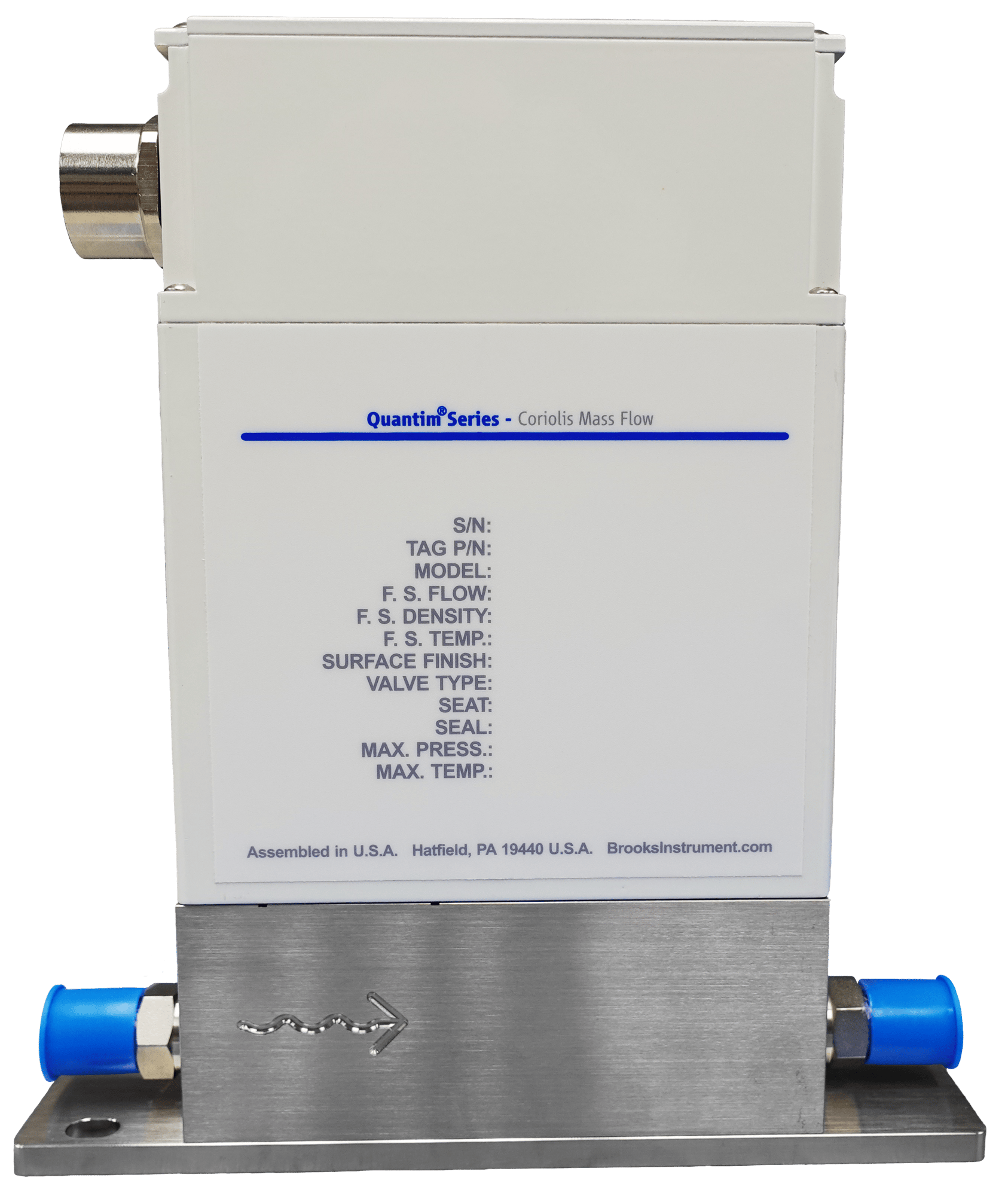

Quantim® QMC Coriolis Mass Flow Meters & Controllers

New third-generation Quantim® QMC Coriolis flow meters are ideal for very low-flow gas and liquid measurement and control applications.

Achieve the most accurate, stable, repeatable and reproducible measurement and control of very low flow rates of liquid or gas with the new series of Quantim® QMC Coriolis flow meters and controllers from Brooks Instrument.

This third-generation Quantim® QMC Coriolis flow meter is engineered to improve process quality, production yield and throughput and reduce scale-up time from lab to pilot plant to production. The devices use a modern IoT-equipped digital architecture that, combined with the next-generation sensor design, enables faster response time with little to no overshoot when adjusting gas or fluid flow, improved zero stability and expanded I/O options.

In addition, Quantim® QMC Coriolis flow controllers provide multivariable outputs, including mass flow, volume flow, density and temperature. They also include a suite of advanced alarms and in situ diagnostics that actively monitor the process to identify system issues earlier and alert operators when mass flow controller maintenance or calibration is required.

Features

- True mass flow measurement

- Accurate density measurement

- NEW I/Os: 0-10 Vdc, 0-20 mA, RS485 S-Protocol

- Variety of material options, enclosure types and area classifications available

- NEW easy-to-access external service port

- NEW Quantim® QMC Coriolis series is form-, fit-, and function- compatible with prior Brooks Instrument Quantim® models

Applications

- Catalyst research

- Mass balance calculations in chemical pilot plants

- Liquid precursor delivery to vaporizers

- Precision coatings

- High-accuracy filling stations

- Metering pump feedback/control loop

- Vacuum processes

- Semiconductor wafer processing

Benefits

- Process chemistry and/or process conditions can be altered without the need to change or recalibrate the measurement system

- With an all-stainless steel construction, Quantim® QMC is compatible with most process fluids

- Accessible via a 2.5 mm jack plug, the external service port coupled with our free downloadable Brooks Expert Support Tool (BEST) software, facilitates enabling the on-board alarms and diagnostics for enhanced process monitoring and predictive maintenance, simplifies installation, supports troubleshooting and calibration verification

| Type of Media | Gas/Liquid |

|---|---|

| Flow Measuring Principle | Coriolis |

| Flow Range | 10 - 27,000 gram/hr |

| Accuracy Range | Liquid: 0.2% of rate, Gas: 0.5% of rate |

| Repeatability | ±0.05% or ±[0.5 x (zero stability/flowrate) x 100]% of rate whichever is greater |

| Max Pressure | 1500 psi |

| Operating Temperature | 0°C - 60°C |

| Ingress Protection | IP40, IP65, IP66 |

| Measure/Control | Measure & Control (Controller), Measure Only (Meter) |

| Max Flow | 450 g/m |

| Max Temperature | 60 celsius |

| Accuracy (% of rate) | ±0.2%, ±0.5% |

| Seal Option | Elastomer |

| Connectivity | Analog (0–5 V), Analog (0–20 mA), RS485 |

Use the following guide (model code information from data sheet) to translate the CAD configurations available below. If you need assistance or can’t find what you’re looking for, please contact Applications Engineering or your local Brooks Instrument representative.

Example: QMC - C - B - A - 1L - 1 - A

| Meter Series | Type | Valve Type | Enclosure | Process Connections | Electrical Connection | Inline Filter |

| QMC | C - Controller | A - No Valve | A - IP40 | 1A - Std Body - 5/16" - 24 UNF | 1 - 15 pin D-type | A - None |

| M - Meter | B - Normally Closed | B - IP40 | 1B - 1/16" Tube Compression | 3 - PG11 Cable Gland | B - In-Line Cartridge Filter, 10 Micron | |

| C - IP66 | 1C - 1/4" Tube Compression | 4 - 1/2" FNPT Conduit | C - In-Line Cartridge Filter, 20 Micron | |||

| D - IP65 | 1D - 1/8" Tube Compression | 6 - M20 Conduit | D - In-Line Cartridge Filter, 30 Micron | |||

| I - IP65 | 1G - 6mm Tube Compression | E - In-Line Cartridge Filter, 40 Micron | ||||

| J - IP65 | 1J - 1/8" NPT(F) | F - In-Line Cartridge Filter, 1 Micron | ||||

| 1K - 1/4" NPT(F) | Z - Filter Housing Only / No Filter Element | |||||

| 1L - 1/8" VCR | ||||||

| 1M - 1/4" VCR | ||||||

| 1P - 1/4" VCO | ||||||

| 2A - 3.2mm UPG |