Mass Flow Controllers Deliver Precise Gas Flows to Produce Cell-Cultured Meat

The process of cell-cultured meat production begins by sourcing real cells from live animals, including livestock, chicken, and fish. These cells are then nurtured in bioreactors where they require accurate gas flow measurement and nutrients. Within weeks, the cell-cultured meat products are ready for the food supply chain.

A cultured meat company required an automated bioprocessing system for their production scale up. The company partnered with an original equipment manufacturer (OEM) for this system. Since the bioprocess system required accurate and repeatable gas flows to cultivate the meat, the OEM reached out to Brooks Instrument for mass flow controllers.

Application Requirements

In order to grow, the cells are placed in a bioreactor where they are fed sugars, salts, vitamins, and amino acids. In addition to these nutrients, there are crucial measurements to be monitored in the bioreactor - the pH level must be accurately controlled along with the amount of dissolved oxygen (DO) needed for the recipe. To maintain tight control of the pH and DO, Brooks Instrument SLA Series Biotech mass flow controllers were selected to measure and control nitrogen, oxygen, air and carbon dioxide to nurture cells at scale.Highlights

- High turndown ratio needed for maximum process control

- Bubble tight shut off required to prevent O2 leakage into the reactor

- Certificates required for compliance

- Advanced alarms and diagnostics for predictive maintenance

- Precise and repeatable flow of the four gases to maintain recipe control through the industry proven Brooks Instrument mass flow controllers known for stable and reliable gas flow measurement and control

Process Solution

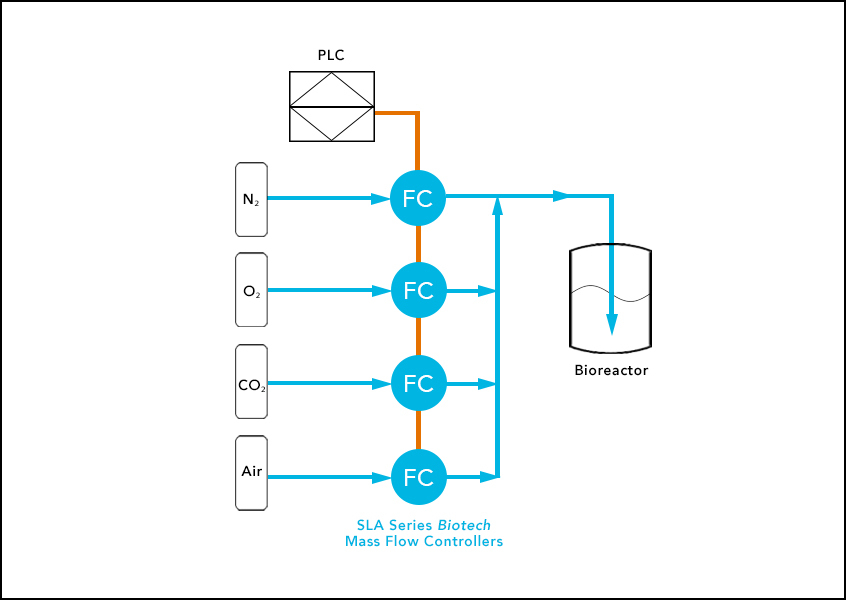

Given the process requirements of the cultured meat company, the flow experts at Brooks Instrument recommended the SLA Series Biotech mass flow controllers with the Premium options package and the EtherNet/IP protocol. Through the EtherNet/IP protocol, the end-user can connect directly to the PLC. Since the SLA Series mass flow meter and controller offers many advanced alarms and diagnostics that provide data to manage your process better, the end-user can configure the PLC to monitor for errors such as restricted flow, backstreaming and many other adverse process conditions. For instance, if an alarm goes off due to a restricted flow upstream in the process, the technician can resolve the issue immediately preventing unnecessary waste and system maintenance thus improving overall yield.

Flow Scheme

Another advantage of the SLA Series Biotech mass flow controller is the enhanced valve tuning that offers a bubble tight shut-off and an extended range of control, up to 250:1 turndown. This allows the OEM to reduce the number of overall mass flow controllers required for air or oxygen streams. Further, the end-user will benefit by having fewer units to maintain, which will aid in reducing the total cost of ownership.

In the cell cultured meat process, using Brooks Instrument SLA Series Biotech mass flow controllers offers several advantages for the customer to produce their product in a stable, repeatable environment with minimal downtime. In this example, the Brooks Instrument mass flow controller solves customer pain points by offering increased turndown, the necessary certificates required for compliance and advanced alarms and diagnostics, all while minimizing the total cost of ownership, for extended savings over the life of the equipment.

As the cultured meat industry continues to grow rapidly, Brooks Instrument, with its proven reputation in precision flow measurement and control, is ready to provide expert knowledge of critical gas flow control in bioreactors to support the growing demand of the global food supply.