Accurate, Stable Gas and Liquid Feed Delivery for Titanium Nitride Coatings

Titanium is frequently used in these applications to create an extremely hard Titanium Nitride (TiN) coating on the target product. Due to its golden appearance TiN coatings are often used on jewelry, household fixtures and automotive trim for decorative purposes. Similar coatings are also used as a non-toxic surface for medical devices and equipment. These types of coatings are now also being applied in advanced biomedical device applications including in-vivo biosensors.

Application Requirements

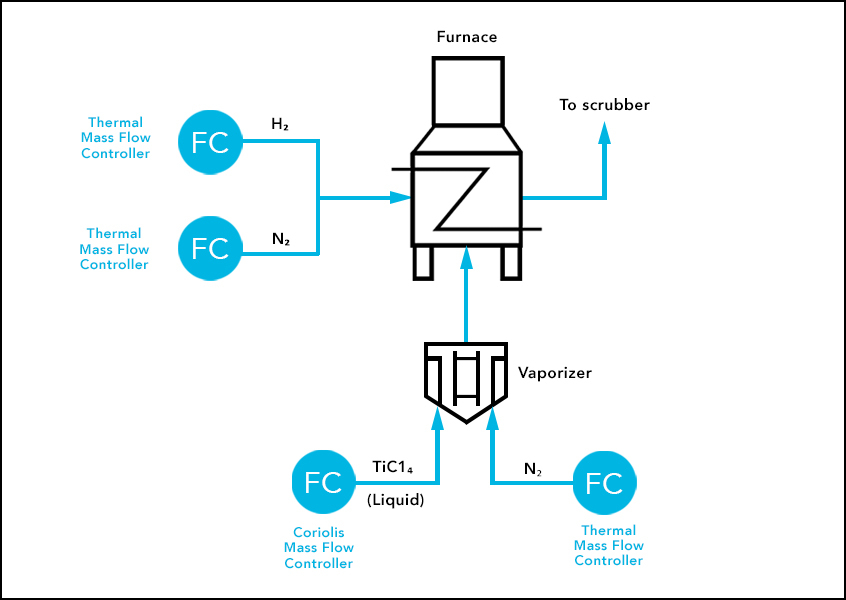

The CVD process is commonly used to create titanium nitride coatings. In this process, several chemicals (TiCl4, N2 and H2) are fed into a furnace where they react at an elevated temperature to create TiN, which deposits on the surfaces as a coating. Critical to the integrity, proper thickness and uniformity of the coating is ensuring the accurate delivery of these materials into a furnace.

TiCl4 will be in a liquid form, and must be vaporized to properly react with the other gases to ensure consistent results.

Care must be taken to minimize contamination that can affect the integrity of the coating. Leaks or o-ring permeation in the system can lead to contamination from the room air. Improper vaporization of TiCl4 can lead to contaminated gas mixtures being delivered to the furnace.

Process Solution

Brooks Instrument SLA5800 Series mass flow controllers & meters (MFCs) provide an excellent solution for accurate, repeatable delivery of the gas components. Several different signal options are available: analog (0-5 VDC or 4-20 mA) or numerous digital protocols, including Ethernet/IP and PROFINET. This allows for a versatile interface to the control system.

With high accuracy, repeatability and superior long-term zero stability, SLA Series MFCs provide a highly reliable, leak free component critical to the CVD system, yielding excellent results at initial startup through the entire life of the CVD process. The SLA Series has many options available to tailor the MFC to the specific application, from different process connections to Hazardous Area ratings on SLAMf Series mass flow controllers & meters.

A Brooks Instrument Quantim® Coriolis mass flow controller is used for control of the liquid feed of TiCl4 to a vaporizer, such as the DLI vaporizer, developed by Brooks Instrument and available through Ceres Technologies under a license agreement. This vaporizer system uses a gentle vaporization technique to ensure high integrity of the TiCl4 supply to the furnace. The liquid feed to the vaporizer is combined with a carrier gas, such as N2, reducing the required heat to vaporize the TiCl4. This eliminates decomposition of the TiCl4 due to excess heat, providing a consistent vapor into the furnace.

If your application is sensitive to moisture or requires high purity, Brooks Instrument also has a variety of solutions available to suit these needs.