Wastewater can carry harmful bacteria and diseases so it must be treated and disinfected at a wastewater treatment plant. Once this process is completed, the water is pumped into a nearby river or bay.

Photo Courtesy of City of San Mateo, California

Application Requirements

The San Francisco Bay area is currently depending on an ageing sewage system and wastewater treatment plant. Typically, sewer pipes have an average lifespan of 50-60 years; however, many of the pipes in the Bay area were constructed between 1900-1960, placing them barely within their useful lifespan. Additionally, the infrastructure is prone to failures including sanitary sewer overflows that leak diluted raw sewage and pollutants onto communities’ streets and into creeks, beaches, and the Bay causing public health and environmental concerns.

Recently, $1 billion was invested on a 10-year capital improvement infrastructure initiative known as the Clean Water Programme. The programme will support the San Francisco Bay area’s growing population of approximately 170,000 residents by repairing, replacing, and upgrading sewer conveyance including the building of a new wastewater treatment plant. More specifically, wet weather sewer capacity assurance will be built to prevent any overflows. Finally, the wastewater treatment plant will also abide by current and future regulatory requirements.

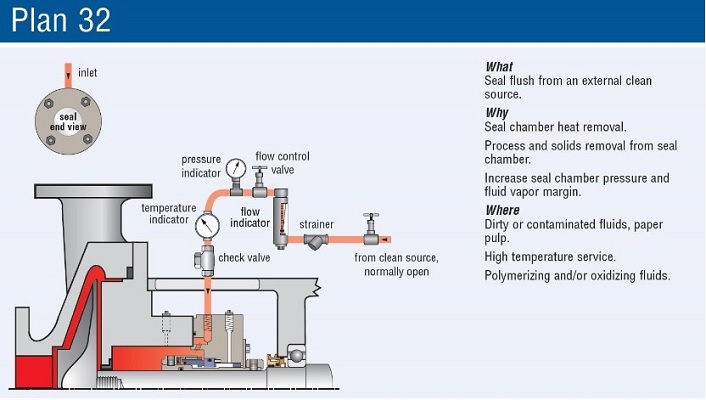

One significant component of the wastewater treatment plant are submersible pumps. The submersible pumps maintain the wastewater flow throughout the piping systems. These pumps have protective seals preventing any leakage as their shafts rotate at high speeds to maintain the flow of water. According to

Pumps & Systems’ Jussi Sorvoja, each seal type has its own specific seal water flow and pressure requirements, and if exceeded, system failures may occur. Only a minimal amount of seal water is needed to cool and lubricate the seals and the rotating shaft in addition to flushing out any impurities.

Process Solution

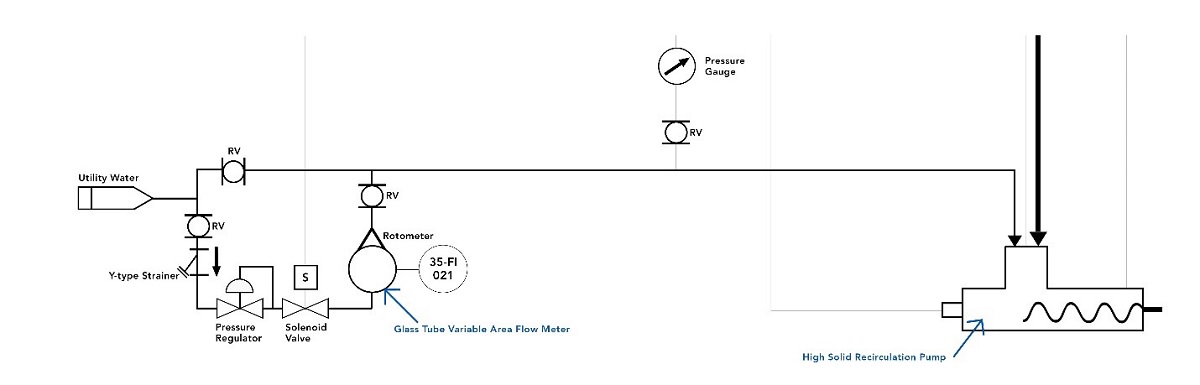

Oftentimes, systems consume too much seal water resulting in costly water consumption. In an effort to control seal water and pressure, variable area rotameters are utilised due to their valves and metering tubes as these adjustable features show the flow readings and control pressure of the seal water. Jussi Sorvia also mentions, “Compared with unmetered systems, flow meters can reduce seal water use in systems by up to 90 percent. They also help seals perform at their peak by maintaining proper seal water pressure and flow.”

Drawing courtesy of Flowserve depicting a general schematic of seal pump systems.

Glass Tube Variable Area Flow Meter in flow scheme

One of the companies supporting this programme, a control system integrator, reached out to the experts in flow and pressure control instrumentation at Ponton Industries. The integrator required eleven flow control meters or one meter for each of the eleven submersible pumps. As part of their business of providing tailored customer support, Ponton Industries recommended the Brooks Instrument GT1600 Series variable area flow meter based on the following parameters:

Instrumentation Highlights:

- Adjustable scale to compensate for variations in seal water flow and pressure

- Viewing window of the glass tube can be rotated at 360° and 180° to easily monitor the flow process

- Save money on seal water with integral valves and metering tube

- Avoid utility expenses as no power source is required

- Maintain the seals on the pumps due to seal water application, when necessary

Watch this GT1600 Series features video to learn more:

Upon completion of the project, the plant will treat 12 million gallons per day during summer months and will effectively manage up to 8 times greater than normal flows. What can be viewed as a small component compared to the overall wastewater treatment plant, the Brooks Instrument GT1600 Series variable area flow meters enable cost savings by controlling and conserving seal water as well as protecting and maintaining the submersible pumps through the efficient use of seal water.

Component datasource missing. Select a datasource for this component.