In my

last post, we discussed several applications for mass flow controllers where precise flow control is needed despite backpressure changes. I introduced a flow effect called choked flow, which many of our customers use in these applications to ignore downstream pressure changes. This is also referred to as sonic flow or critical flow.

To my flow-savvy readers: You'll notice that I'm discussing choked flow in conceptual terms rather than demonstrating complex formulas and calculations. Don't be alarmed! Feel free to post any additional thoughts you have on this topic in the comments below.

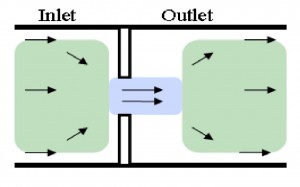

The sketch to the right shows gas flow through a typical orifice. The green shaded areas are high pressure, low velocity flow areas, and the blue area is a

low pressure, high velocity flow area. Inlet gas flow speeds up as it compresses to pass through the orifice, then re-expands and slows back down on the outlet side. The flow rate through the orifice is primarily set by the inlet and outlet pressures, as well as the diameter of the orifice opening. Gas temperature also plays a part.

A gas

expands in a space as its molecules collide with whatever else is present. (pipe walls, other gas molecules, etc.) Every gas expands at its own rate, and

pressure increases in a gas are a result of squeezing more gas molecules into the same amount of space. Applying these factors to the orifice flow pictured, gas expansion causes some of the molecules that are expanding in the green area on the outlet side to collide with and deflect the "fast" molecules in the blue area. If the pressure rises in the green area on the outlet side, it's because there are more gas molecules present in the same amount of space.

More molecules in the green outlet area mean that more molecules deflect the "fast" molecules in the blue area. This reduces flow velocity in the blue area, which is what reduces the flow rate passing through an orifice at higher backpressures. If the pressure drops in the green outlet area, it means that fewer molecules are present in that space, which results in fewer deflections of "fast" blue molecules. This causes a higher velocity in the blue area, and thus a higher flow rate when the backpressure drops.

Choked flow occurs when the flow velocity in the blue area reaches

the speed of sound. At this velocity, the molecules in the blue area are essentially traveling faster than the molecules in the green outlet area are expanding. So deflection between molecules at the blue/green border doesn't reduce velocity in the blue area. With a fixed inlet pressure, the outlet pressure can change over a wide range without changing the mass flow rate as long as the conditions to maintain choked flow remain in place.

So how can we reach the conditions needed to maintain choked flow? We'll cover that in our

final post in this series.

Component datasource missing. Select a datasource for this component.